High-precision custom CNC machining of bipolar plates is a key component manufacturing technology for new energy sectors such as hydrogen fuel cells and electrolyzers. Here's what we can do for you:

Step 1: Materials

Materials for bipolar plates usually include:

Metal materials: such as titanium alloy (TA1, TA2, TC4, etc.), stainless steel, nickel, etc. These materials have good corrosion resistance and mechanical strength.

Graphite material: The graphite bipolar plate is CNC machined and has good consistency, weather resistance and thermal management performance.

2. Processing technology

CNC machining is a high-precision manufacturing process suitable for the customized production of bipolar plates. Its features include:

High precision: CNC machining can achieve extremely high dimensional accuracy, such as ±10μm in fuel cell bipolar plate runner processing.

Customization: Machining according to drawings or samples provided by customers, supporting complex designs and microporous structures.

Surface treatment: The surface of the processed bipolar plate is smooth, smooth and without defects.

3. Application field

Bipolar plates are widely used in the following fields:

Hydrogen fuel cell: As a key component of the stack, it provides gas flow channels and prevents gas collusion.

Electrolytic cell: used for electrolysis of water to produce hydrogen, with good corrosion resistance and electrical conductivity.

Other new energy fields: such as electrolytic production of non-ferrous metals, wastewater treatment, etc

4. Customized services are supported in the following ways:

Drawing processing: processing according to the drawings provided by customers.

Sample processing: Copy and optimize according to the samples provided by customers.

Coating services: Some manufacturers also offer precious metal coating or other coating services to improve the performance of the bipolar plate.

Step 5: Advantages

Advantages of CNC machining bipolar plates include:

Good consistency: highly consistent size and electrochemical performance.

Short production cycle: 15-22 days.

Low cost: Compared to traditional metal bipolar plates, graphite bipolar plates cost less.

Strong corrosion resistance: titanium alloy and graphite materials have good corrosion resistance.

If you need to know more or customize high-precision CNC machining of bipolar plates, welcome to contact us from this platform to provide you with one-stop processing services.

| Processor | |

| Clockspeed | 100mhz |

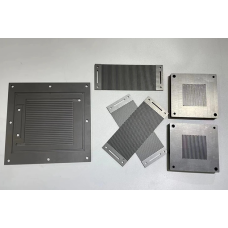

High precision customized CNC machining parts bipolar plate

- Brand: Apple

- Product Code: Product 15

- Reward Points: 100

- Availability: 990

- $100.00

-

$90.00

- Ex Tax: $90.00

- Price in reward points: 400

-

- 10 or more $88.00

- 20 or more $77.00

- 30 or more $66.00